WORKING PRINCIPLE

The idea

A high frequency opcal measurement system, embedded in a zero-fricon rod launch mechanism guaranteeing lab-quality repeatability, with a temperature monitoring, dedicated soware and full portability, become a groundbraking innovaon in viscoelasc materials assessment and characterizaon.

The output

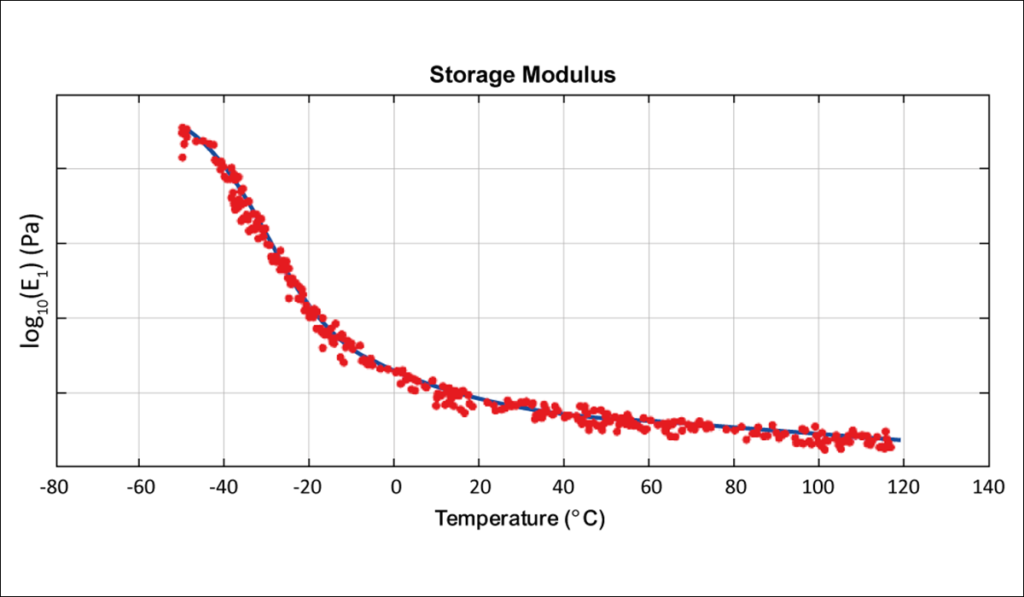

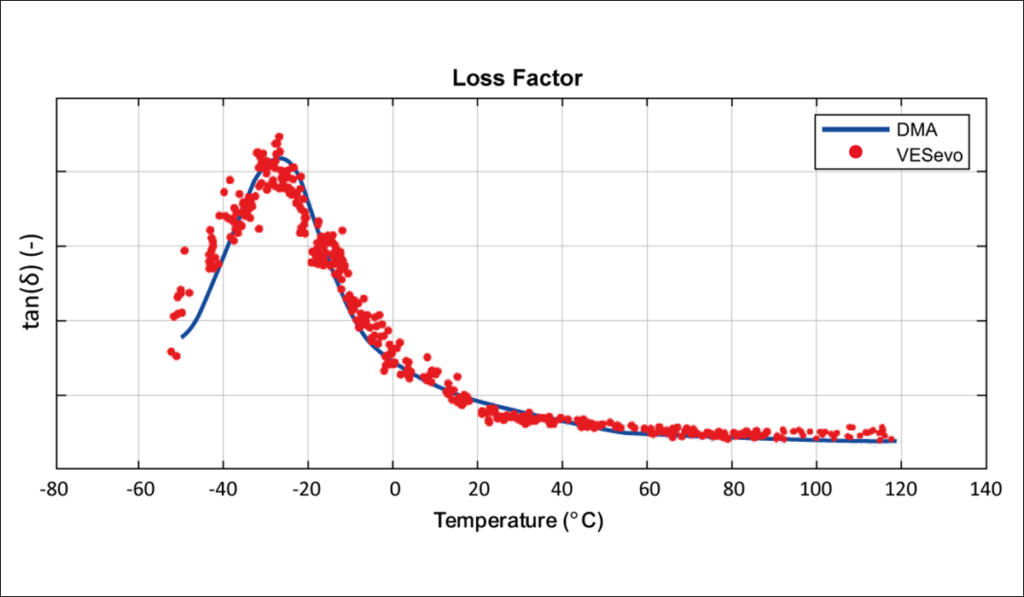

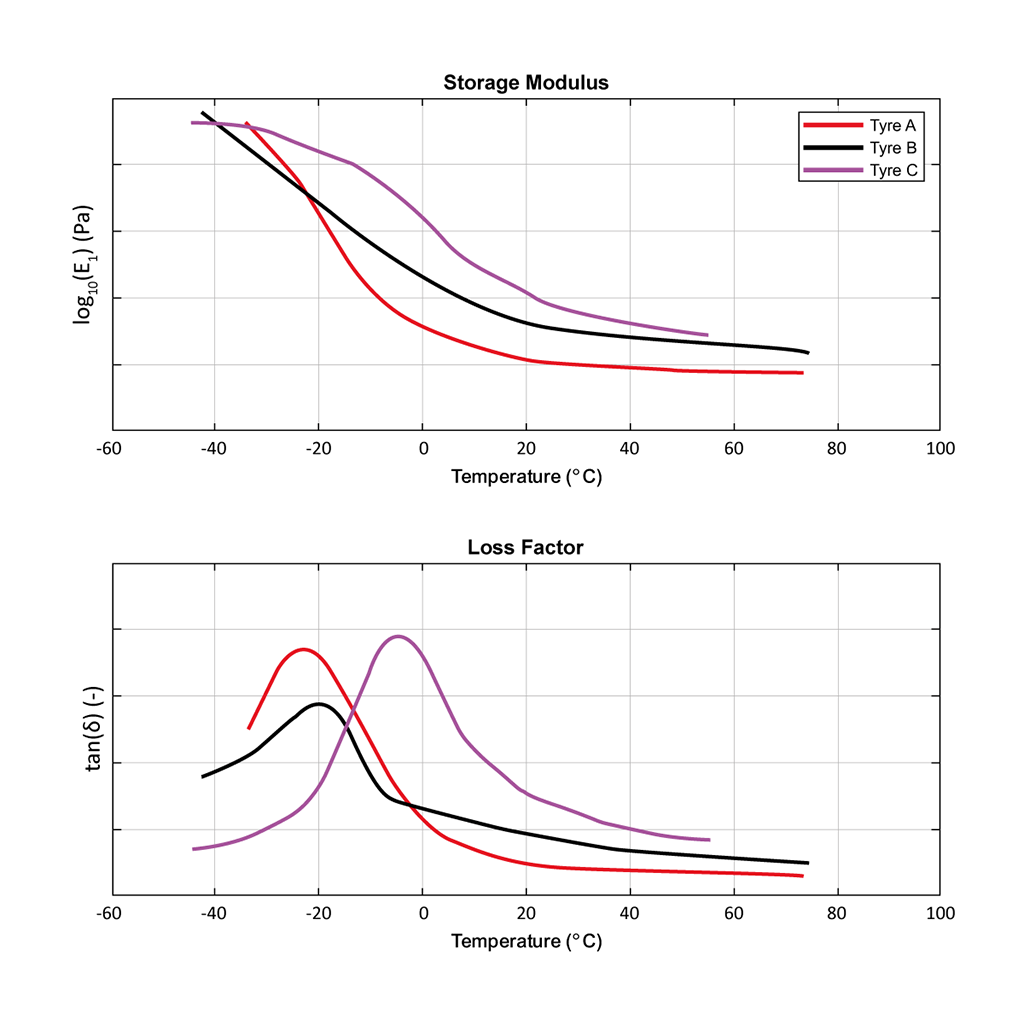

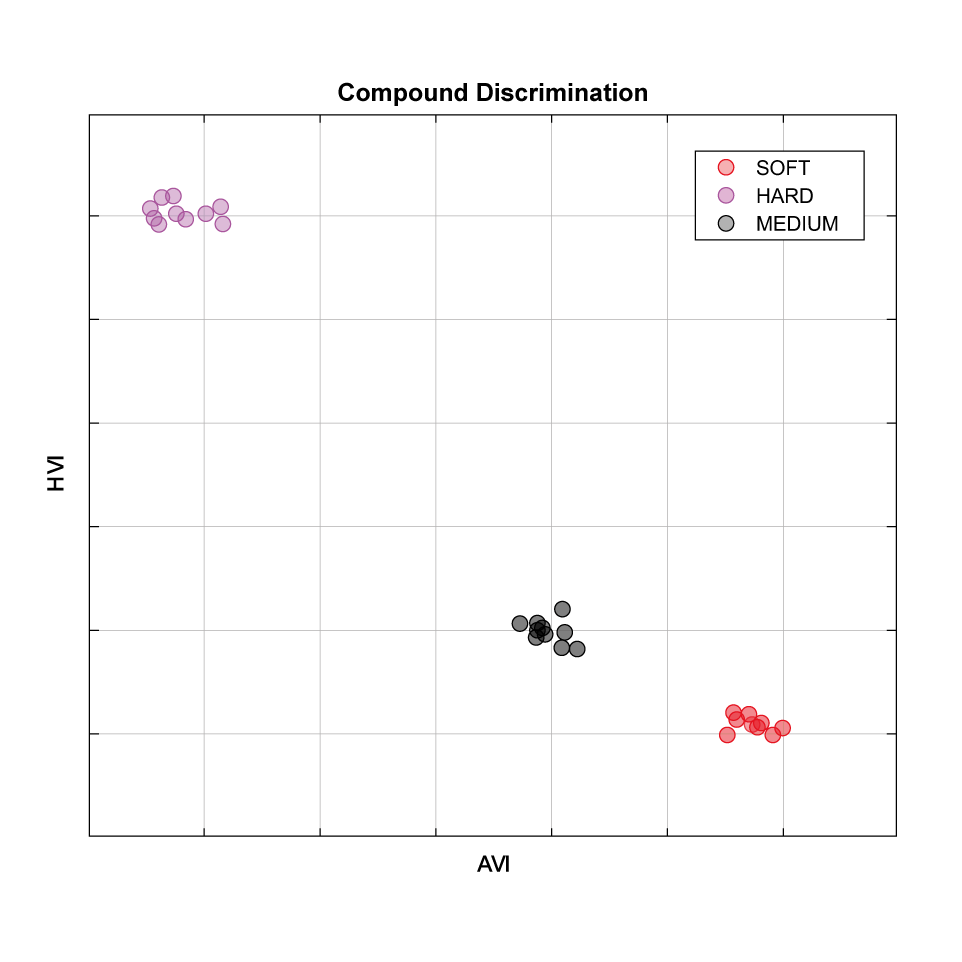

VESevo provides the characterization of a viscoelastic material in terms of the widely used indexes E’ (storage modulus, related to the “in-phase” elastic response) and tan(δ) (tangent delta, linked to loss factor and to the dissipative response).

Such variables are deeply linked to the attitude of the material to generate “grip”, respectively as concerns adhesive and hysteretic friction generation mechanisms.

The data provided by VESevo test are highly reliable and are comparable, in terms of quality, to the results usually obtainable by a DMA (Dynamic Mechanical Analysis) test. With the advantage, respect to DMA, that VESevo methodology is faster and cheaper than DMA and completely non-destructive, allowing to monitor the material properties during its whole lifecycle.